In this article we want to introduce you to how medical cannabis glass is produced, especially in the USA, and what to look out for. A highly potent substance with an explosive, difficult production. The starting material for this is BHO (Butane Honey Oil).

When trying to produce a cannabis concentrate, there have often been incidents with ignorant beginners. The concentrate has burned badly or there has even been an explosion. Dilettantely made extracts can have health consequences, so it must be warned against making them yourself without sufficient knowledge. The solvents used are highly flammable, explosive and difficult to handle, so it is better to leave the extraction to the professionals.

What are cannabis concentrates?

The High Times Cannabis Cups now recognise the concentrated forms of cannabis extracts as an increasingly important category in the competitions. These concentrates are currently in high demand, especially in the USA. At the High Times events, the stands with the clear plates attract a lot of attention and interest from the visitors in particular. The extreme boom around cannabis concentrates and the resulting industry in America could also have detrimental effects for cannabis legalisation in the long run. Self-regulation of this new industry is necessary, as is a scientifically sound approach to the production of these products.

Dabs are highly concentrated cannabis resin. The main components are cannabinoids (e.g. THC and CBD) and various terpenes and terpenoids, which are responsible for the myriad flavours and aromas of marijuana. Terpenes and perpenoids are also responsible for the different psychoactive effects of the individual strains.

Hashish is traditionally concentrated without solvents and is rubbed with the hands, sieved or obtained by water-ice extraction. Hashish is thus a collection of resin glands and trichomes as well as plant residues. Even the best bubble ice hash contains some plant residues, the hand-rubbed hash even more.

In the pure concentrates that have been produced correctly, the plant residues are filtered out. The concentrate therefore contains only the resin from the trichomes and the essential oils. These concentrates are attractive in many ways for the medicinal field and users can achieve very high and strong effects with a minimum amount.

There are three forms of concentrates:

- Glass: plates as if made of glass (shatter, fragile)

- Cannabis Budder or Wax

- Honey oil, butane hash oil

![]()

These three basic forms are often renamed and used in different products or even made into powder. An extract can also contain other undesirable substances such as pesticides or fertilisers and even have them in concentrated form if these have previously been added to the plants used. A particularly responsible handling and renunciation of chemical additives and fertilisers during cultivation is therefore enormously important in order to produce concentrates that are harmless to health.

Only the best and highest quality flowers are used in the production of cannabis jar to obtain a healthy and very strong end product. All flowers must be healthy, free from mould, mildew or other fungi. Extracts are stripped of unwanted and unhealthy substances such as chlorophyll, fats etc. during the production process. These would also make an unintentionally scratchy and unpleasant smoke.

Many amateur extractors believe that all the work is already done after the first extraction, but the professional knows that now the real extraction process begins. All the other steps that follow are at least as important.

Winterization - Frosting for Cannabis Lovers

The starting material is concentrated resin that has been extracted with butane, nitrogen or CO2. It does not matter which of the three substances was used, because all of them lead to good quality and can dissolve considerable amounts of cannabinoids, terpenes and terpenoids. However, all three also dissolve minute amounts of chlorophyll, lipids, plant fats and waxes.

- If CO2 or nitrogen was used for extraction, the crude extract should be placed in ethanol (organic alcohol) and then heated slightly to 50° C until the extract dissolves in the alcohol.

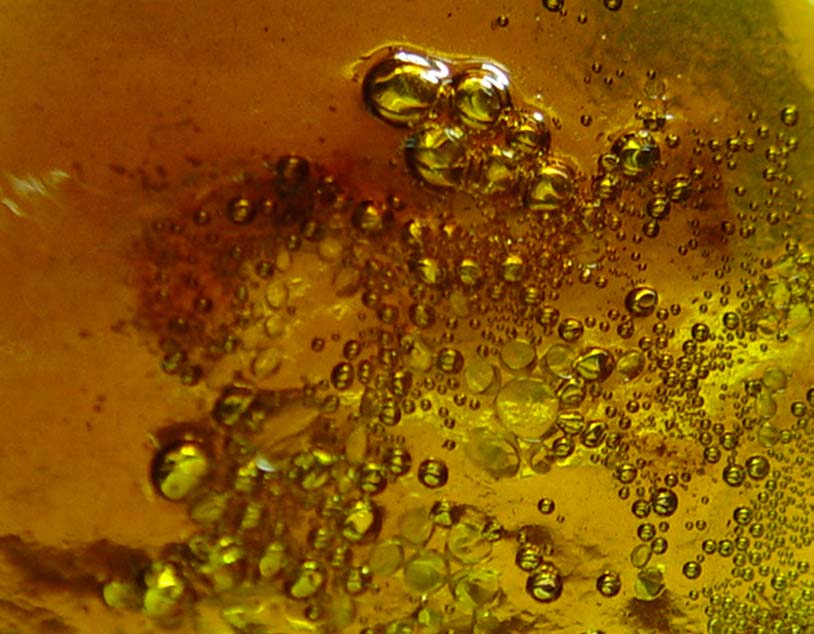

- For extracts made with butane gas, mix one part ethanol with two parts extract. The cannabinoids bind to the alcohol while the butane evaporates. A lack of knowledge or carelessness can lead to explosions or fires. After the cannabinoid solution has been added to the organic alcohol, it is filled into sealable plastic bottles. It is extremely important that all butane, nitrogen or CO2 has evaporated completely. This can be seen by the fact that the liquid no longer bubbles when it is stirred.

The containers are then sealed tightly and placed in a freezer for at least 48-58 hours (min. -15° C). After freezing, the canabinoid alcohol solution is carefully poured through a fine cloth sieve/coffee filter (20 micron filter). The sieve is changed frequently and not too much liquid is poured in at once, so that unwanted plant particles are not pressed through the sieve by the excessive pressure of the liquid. The sediment with the plant particles is not poured through the sieve and remains in the container. In order to dissolve the remaining cannabinoids from the sediment, the container is filled with alcohol and heated to 50° C. Then the whole thing is frozen again. Then the whole thing is frozen again and filtered as described above.

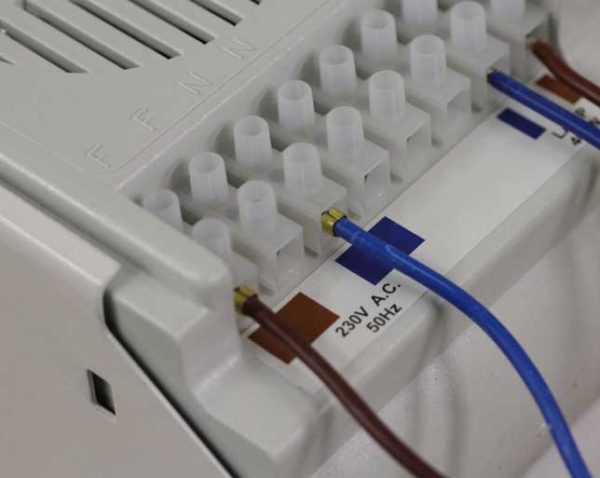

The filtered solution must now be dried. For this purpose, the extract is poured into a vessel lined with parchment. Drying must take place in a clean, dust-free and dark environment, paying particular attention to very good ventilation. Under no circumstances should smoking, embers, fires be lit in the same room, nor should any electrical appliances be operated, such as sodium vapour lamps, dryers, washing machines, refrigerators, etc., nor should any light be switched on or off by a light switch. Any cigar smoke must be avoided at all costs, as the alcohol vapours produced are highly explosive and even a small spark is enough to cause an explosion. Likewise, inhaling the alcohol vapours is harmful to health. For this reason, this step is often carried out outdoors, thus significantly reducing the risk. The vapours can escape immediately. It usually takes 24-48 hours for the concentrate to dry. This depends on the respective air movement, temperature and humidity. No heat or warmth is added here, as this would only unnecessarily worsen the aroma and essential oils would evaporate more easily. Alcohol and water should dry as much as possible.

The result is now a sticky liquid, but it has not yet dried completely. It still contains tiny amounts of alcohol and water trapped inside. When this liquid is heated in the next step (approx. 50° C) to evaporate even more water and alcohol, an oleoresin is finally produced. An oleoresin is a mixture of resin and oil. This must be dried further. For this purpose, there are special vacuum-heat-drying ovens for the laboratory, which create an extreme vacuum and serve for degassing. They hardly destroy any terpenes or terpenoids and produce medicinally pure cannabis extract.

This glass concentrate, i.e. the oleoresin, can now be processed further by pouring it into a glass casserole dish and heating it to 50° C. The oleoresin is then heated. It begins to melt. At this point it is stirred and beaten vigorously until it reaches a light colour and is no longer sticky. A hot plate is often used for this. This takes about 20 minutes. If the final product is light in colour, this indicates that the buds have been harvested and stored properly.

Important for the production of cannabis glass:

- The extract and end product must never be exposed to light or even direct sunlight. The UV rays break down THC and other active substances.

- Flowers that are used should be stored frozen and must not be exposed to light after harvesting

- Only absolutely excellent, healthy buds are used, which are stored in the best possible way. This is a basic requirement for a high-quality end product.

- For the production particularly resinous and strong varieties used.

BHO products for extraction and further processing in our shop: