The production of BHO is often not a simple matter and there was sometimes confusion about when to use what and how. There are a thousand different opinions on this. I have tried to break it down again in detail, I hope it is somewhat understandable and helps you further, I have now also integrated winterisation into the process, because I don't think it was always clear where it starts and then different methods flow into each other in a slightly strange way. As with the Grow, all I can say is don't get angry if it doesn't work at the first attempt. The greatest masters often come from a few failures, as if it had to be that way in order to become good 😉

The following are the possibilities for making shatter the way I do it and the way I get along best with it. There are many opinions on the subject and also variations on individual steps, but I find this one the best 😉

Step 1: Preparation

Prepare all necessary counterparts such as extractor + filter, glass tub, hot plate, gloves, etc. Disinfect vessels and extractor with alcohol.

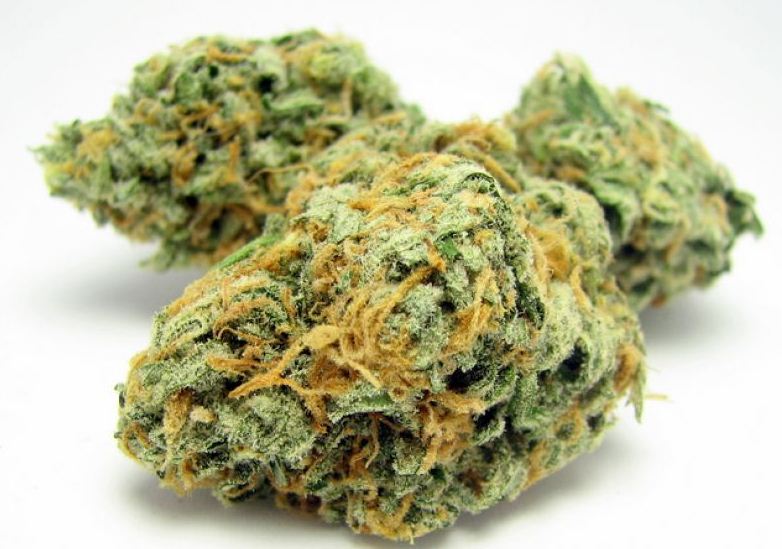

Starting material: Absolutely high-quality, resinous and naturally fungus-free flowers that have been properly dried and stored are used as starting material. These should be very dry and are best stored in the freezer before extraction. The flowers are only crushed, if at all, if they are very large and extremely hard, do not witch or grind! For the first pass of extracting, where the "best" and brightest concentrate should come out, the flowers of medium or small size are used.

If you want bright clear shatter at the end, no leaves should be used and the buds should be well trimmed. The golden-yellow absolutely high-quality and best end product does not come out if you use the trimmed leaves. Of course, these can also be processed, but then the end product will usually be much darker and caramel-coloured.

Note: The lighter and clearer the extract, the purer and higher quality it is. This is a sign of quality if both the processing and the raw material have been ideal.

Step 2: Fill extractor

The sieve is placed in the extractor (2 pieces) and it is gradually filled with the uncrushed (barely crushed, not bruised) flowers and each individual layer is pressed tightly with e.g. a bamboo stick, without creating air holes in the extractor. In the first pass of the extractor, the barely or not crushed flowers are used. This produces the best concentrate. I keep it separate from what comes out in the 2nd pass.

The extractor must be completely filled with plant material. If there are not enough flowers, a smaller extractor must be used. This is because air pockets in the extractor would cause the liquid butane to expand into butane gas, which would negatively affect the extraction process.

Step 3 Prepare water bath/heating plate

Fill the glass tub/pot with warm water (max. 60°C) and have a smaller glass tub ready for direct extraction. It is best to use glass for this, because plastic in combination with the butane could possibly dissolve substances from the plastic or other materials and transfer them into the concentrate. I use glass so I can be sure. The temperature of the water bath should not exceed 60°C. Therefore, use a thermometer. Therefore, you should use a thermometer and measure the water temperature. If the temperature is too high, valuable cannabinoids and terpenes are degraded and destroyed, and the end product can become darker.

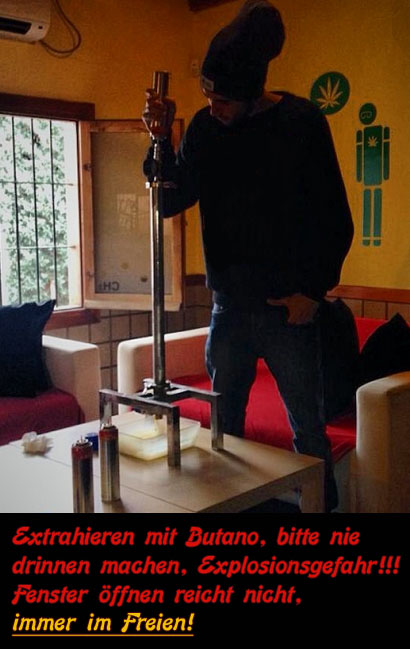

Step 4 Outdoor extraction

For safety reasons, the extraction with butane gas must be always be carried out outdoors. Tight clothing, safety goggles and protective gloves should be worn. The gloves prevent, among other things, frostbite on the hands, the extractor gets very cold during extraction.

The butane gas cylinder is placed on the extractor and pressed through above the glass tank.

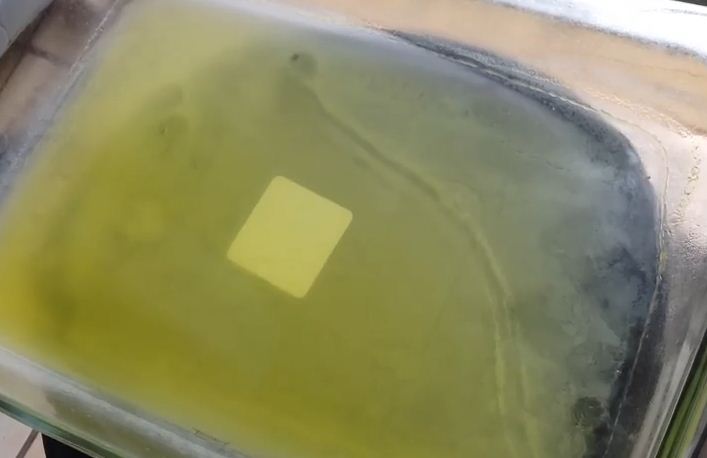

It takes a few seconds for it to start dripping out of the bottom of the extractor. Some concentrate manufacturers first let gas through the tube for 30 seconds, then wait about 15 seconds and continue until the butane bottle is empty. Depending on the case, a second butane gas bottle is now used in the same way. The oil collects in the pan. The butane gas must not be inhaled! During the first run, the cannabis-butane mixture should now be very bright and transparent, if everything has been right.

For the second extraction run, the same material from the extractor can be used again. To do this, take everything out of the extractor, let it dry and put a new sieve (2 pieces) into the extractor. This time it is crushed in a grinder or Häxler and then filled back into the extractor. If this filling is now extracted in the open, a darker and possibly also cloudier oil comes out, because there are more plant parts and chlorophyll in it than in the first very coarse extraction. I keep both extracts separate from each other.

Step 5: After extraction, immediately place in the water bath/on the hot plate.

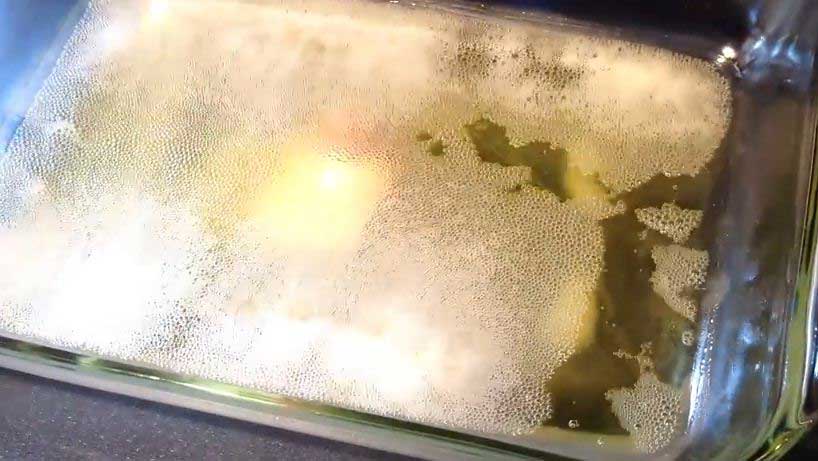

After extraction, the bowl with the oil-butane mixture is placed in the bowl with the warm water (-> water bath, approx. 50°C). The mixture starts to bubble and bubbles rise. This is the escaping butane gas. The extract remains in the water bath/on the hot plate until it stops bubbling and most of the butane gas has escaped, approx. for 30-45 minutes. This process should also be done outdoors for safety reasons.

After 30-45 minutes, a large part of the gas has already escaped, but not all of it. If the oil-butane mixture has a temperature of 21°C, it is safe to bring it inside. to bring.

There are now 2 ways to proceed:

Option I: Further processing without filtering:

Step 6: continue to allow gas to escape on the hot plate.

The liquid oil-butane mixture in its fireproof glass vessel is now placed on the Hot plate at 50°C-60°C. Over time, the extract becomes more viscous and throws bubbles. These can be pricked open so that the gas can escape even better. Wait until the whole thing is no longer liquid but has a viscous, honey-like and very resinous sticky consistency that throws thick bubbles and is mouldable. Now it can be scraped out of the glass jar with a razor blade.

The whole thing is now honey oil and is a cloudy honey-coloured, yellowish mass. This "thickening process", in which the liquid becomes a malleable mass, should not be accelerated by adding temperature and possibly boiling the whole thing down. This takes as long as it takes and you should have patience.

Step 7: Purching with the vacuum pump + chamber

The honey oil can now be placed on a slick pad or other anti-stick surface and put into the vacuum chamber. The vacuum chamber can be placed on a hot plate during the purging process. The Temperature should be approx. 40-60° C and in any case not exceed. Alternatively, the concentrate can be put into the vacuum pump for a few minutes, then onto the heating plate for a few minutes and back into the vacuum chamber, and so on. During purging in the vacuum chamber, the concentrate will bubble and become increasingly clear as more gas escapes. It should remain in the vacuum chamber until no more bubbles appear and it has become clear and completely solid.

This is what the finished shatter should look like now:

Option II: Further processing with filters/winterisation

Filtering or winterisation is used to get even purer shatter that really only consists of pure cannabinoids and terpenes. Filtering removes plant fats and waxes, chlorophyll, plant fibres and particles from the concentrate. This makes it particularly clear and bright and also correspondingly valuable. The smoke is particularly mild. (previously as described in steps 1 -4)

Step 6: Infuse with ethanol

After the oil-butane mixture can be brought indoors at a temperature of 21°C, it is slowly infused with ethanol (suitable for consumption). Mix one part ethanol with two parts extract and stir. Let it stand for 30 minutes until no more bubbles appear. Then stir again and wait another 30 minutes. You can see how the liquid is active.

Step 7: into the freezer

Now fill the whole thing into bottles and put them in the freezer for 48 hours at a minimum of -15°C.

Step 7: Filter

48 hours later, the concentrate-alcohol mixture is now taken out of the freezer and carefully poured through a coffee filter.

Step 8: Allow ethanol to evaporate

Pour the alcohol-concentrate mixture into a glass bowl and place on a hot plate. at 50°C Place a slick pad in the bottom of the glass bowl. If you wish, you can place a slick pad in the bottom of the glass bowl to make it easier to remove the concentrate from the glass bowl later. The alcohol now evaporates. Be careful here, because alcohol vapours are very flammable. It is therefore advisable to do this process outdoors. No joint, no ignition spark, otherwise you'll get a nasty surprise! On the hot plate, the concentrate slowly dries and starts to become clear after some time. To get more alcohol and water out of the concentrate, the vacuum pump and chamber can be used for the drying process.

When the filtered concentrate is completely dry, it is bright, clear and has no enclosed bubbles more. It is now as hard as glass and looks like it too. The shatter is ready 😀