The right lighting is one of the most important main factors when it comes to the healthy development of cannabis plants, the formation of flowers and good yields when growing indoors. It all depends on it, without the right light, nothing will happen.

Cannabis can be grown indoors with special light such as fluorescent tubes, energy-saving lamps, sodium vapour lamps, MH lamps and special plant LEDs. For indoor cannabis cultivation, there are now a wide variety of designs and models with different wattages and lumens.

A complete lighting system for cannabis plants should always consist of the following components: Bulb, reflector, ballast (internal to the bulb or external depending). For a successful grow, the correct colour spectrum of the light is crucial.

The right colour spectrum for cannabis plants - When which lamp?

Fluorescent tubes

White and blue light are important for the growth phase of cannabis plants. Fluorescent tubes provide white light and can be used in cultivation during the growth phase.

Fluorescent tubes are available in different diameters. For cannabis cultivation, fluorescent tubes with diameter T2 diameter: 7 mm), T5 (diameter: 15.8 mm) and T8 (diameter: 25.4 mm), T12 (diameter: 38 mm) are mainly used. For each diameter, there is a corresponding fitting in which the lamp fits.

Properties of fluorescent tubes :

- depending on type and length with 34W, 40W and 54W

- the ballast for the fluorescent tubes is often already built into the fitting.

- they consume much less energy than NDL lamps, but also produce significantly less light.

- for best results, the distance from fluorescent tubes to plants should be relatively low: 5-10 cm

- The light emission is strongest in the middle of the tube and decreases slightly towards the end of the tubes.

- CFLs are available in different colour spectra with 2700K (Warm White), 3500K (Neutral White), 4100K (Cool White), 5000K(Full Spectrum), 6400K (Daylight)

- are often used in cannabis cultivation from germination to harvest, especially suitable for the initial phase and the growing phase

- They lose light intensity over time, so they should be replaced as soon as they emit only 70%-90% of the specified light or start to flicker. This is a sign that the fluorescent tube will soon burn out.

- The service life of CFLs: max. 15 months with 18 hours of running time per day.

- Only low heat generation

Fluorescent tubes with the following colour codes can be used for growth:

- 82(7) extra warm white -> well suited

- 83(0) warm white -> well suited

- 84(0) cold white -> well suited

- 865 cold white -> very suitable

- 93(0) warm white -> very suitable

- 94(0) cold white -> very suitable

- 95(0) cold white -> very suitable

- 96(5) Daylight -> very suitable

Fluorescent tubes are available in different lengths:

- 59cm -> 18W (approx. 1300-1600 lumen)

- 90cm -> 30W (approx. 2500 lumen)

- 120cm -> 36W (approx. 3200 lumen)

- 150cm -> 58W (approx. 5200 lumen)

Energy saving lamps (ESL)

There are also special plantEnergy saving lamps (ESL) for the grow area are available, which provide white and blue light and are suitable for the growth but also the flowering phase: e.g. ESL AgroLite 250W for growth, colour spectrum (2700k), 16,000 lumen. There are ESLs with a red spectrum for flowering, with a blue spectrum for growth and with a dual spectrum (flowering + growth).

They are CFL lamps that already contain the ballast in the bulb itself at the rear end.

Properties of energy-saving lamps:

- available with 100W, 150W, 200W, 250W

- they can be used from germination to harvest, but do not provide the same high light intensity as NDLs.

- In the higher wattage range (from 100W), you need a special E40 lampholder.

- they need approx. 5 minutes warm-up time until full brightness is reached

- they are available with different light spectra: Daylight, Cool White, Warm White

- Perfect for gardens with limited budget and space

- Low heat generation

- the service life depends on the circumstances and the type. Frequent switching on and off shortens the life span. At the end of their life, they provide only 70-80% of the original light output. At this point, they should be replaced (after about 15 months).

Sodium vapour lamps (NDL) / metal halide lamps (MHL)

Sodium vapour lamps (NDL) produce red and yellow light and are absolutely useful and most widely used in the flowering phase of the plant. High pressure gas discharge lamps include: Mercury vapour lamps (outdated and uneconomical), metal halide lamps (blue light) and high-pressure sodium lamps. Metal halide lamps and high-pressure sodium lamps, as well as dual spectrum lamps, are particularly used in cannabis cultivation. They are effective and provide a large amount of light. NDL lamps are available in 150-1000W for indoor cultivation and always require the appropriate ballast. For cannabis cultivation, 250W, 400W and 600W NDLs are mainly used.

Sodium vapour lamps produce an orange light that has high proportions of yellow, orange and red light. Since cannabis plants need mainly red and orange light to develop large beautiful buds, NDLs are primarily used during the flowering period. The combination of sodium vapour lamps and metal halide lamps is also very popular with professional grows that aim for very high yields.

NDLs with dual colour spectrum (red and blue) can be used for both the growing phase and the flowering phase. This results in a more compact growth compared to a metal halide lamp in the growing phase and can be advantageous when space is limited.

Sodium vapour lamps are relatively resistant. However, if they have been in operation for some time, components inside become brittle. A violent impact can then considerably shorten the service life and/or reduce the luminosity. NdLs and metal halide lamps should never be unscrewed while they are still warm. the heat causes them to expand and therefore sit firmly in the socket. They can only be unscrewed with a great deal of force, so it is better to wait. If a bulb breaks when being screwed in and out because too much force was involved, immediately pull out the mains plug and do not touch any of the metal parts inside.

The glass bulb of the NDLs and metal halide lamps should always be clean. It is best to clean them with a clean soft cloth every 2-4 weeks, when the lamp has cooled down. A dusty and dirty bulb will give the plants fewer lumens. Residues of insect repellent, fertiliser or water can also cause deposits on the bulb and reduce the brightness of the lamp. Do not touch the glass bulb with your fingers. When the lamp has cooled down, it can also be cleaned with spirit and a paper kitchen towel. This is good for removing stubborn dirt.

NDLs and metal halide lamps only have a certain service life. After a certain time, their brightness decreases. To determine the brightness or for any other reason, you should never look into the lamp. This can damage the eyes.

Ballasts for NDLs and metal halide lamps:

Every NDL and metal halide lamp needs the right ballast, otherwise the lamp will not work properly or will burn out very quickly. There are analogue and electronic ballasts. The electronic ones produce less heat and are quieter. For insulation not a complete box should be built around the ballast to prevent overheating. There are pre-wired ballasts (with IEC plugs, for example) and ballasts that have to be wired by yourself first. This should only be done by a professional. If you are not sure about this, choose an NDL system that is already wired and that contains all the right components. A lamp kit, e.g. this ....

Each wattage needs the corresponding ballast: for example, a 400W NDL needs a 400W ballast. With modern electronic dimmable ballasts, the wattage can be varied and adjusted accordingly. This gives the grower flexibility and energy cost savings.

Some ballasts can also be connected in parallel and thus used efficiently, provided that the existing circuit can cope with this. This way you can use several ballasts and the resistance is lower, less current is lost along the way. However, this is more a matter for the specialist, because a considerably higher amount of current flows here. Correct earthing is absolutely necessary when connecting several ballasts in parallel.

The ballast should not be touched, examined or anything else while it is in operation. It is under high voltage of several 1000V because of the phase shift that takes place. It should also not be placed on a damp floor. The safest and best solution is to hang the ballast on the wall. Rubber domes for the ballast dampen the vibration and reduce the noise.

A ballast that is less hot runs more efficiently and its bulb burns brighter. A fan can be directed at the ballast for additional cooling. High-quality and expensive units have fans built in. Today's grow ballasts can generally run both NDLs and metal halide lamps.

Properties NDLs and metal halide lamps:

- available for grow between 150W and 1000W, in Europe mainly 400W and 600W lamps are used

- always need the right ballast

- new models and developments offer powerful and optimised light sources

- Only lamps with a clear glass bulb are used for the grow.

- are suitable for seedlings, for the growing phase and for the flowering phase

- if the lamp is switched on and off more than once a day, this represents an additional load and shortens the life of the lamp

- Metal halide lamps have a service life of approx. 12,000 hours with a daily burning time of 18 hours. That is a relatively long time and almost 2 years. It is at the end of its life when the light becomes dimmer and prblems appear when starting. At that point, the metal halide lamps should be replaced. Don't wait until it has burnt out completely, because old bulbs are inefficient and uneconomical.

- Metal halide lamps: A fast flashing pulsating flicker indicates that the arc is flaring 120x per second. If the lighting is otherwise constant, everything is ok and normal.

- especially analogue ballasts have a high weight

TIP: Light sources (NDLs and metal halide lamps) are cheap. It is worth replacing them more frequently rather than continuing with low-power ones and losing yields. If you are going to invest energy, then do it as efficiently as possible.

LEDs

LEDs are now everywhere, in advertising signs, on various appliances and on the Christmas tree. Since LEDs were invented in 1962, they have come a long way. While the first ones had a very low luminous flux, LED technology progressed rapidly, producing much brighter and more efficient LEDs. There are LEDs in the entire visible light spectrum and from ultraviolet to infrared.

Many cannabis growers who cultivate medicinal cannabis use LEDs. They are used in the germination and grow phase, but also during the flowering phase. There are now countless different types of LEDs on the market. In some cases, it is not easy to immediately recognise from the data which LED may be different from another.

LEDs use solid-state semiconductor energy to generate light. The technology is similar to that found in computer circuits. They do not use gas like, for example, NDLs or energy-saving lamps. At the same time, LEDs generate less heat. The luminous efficacy of LEDs increases with high-quality processing and the use of improved materials.

LEDs are available with red (for flowering) or blue colour spectrum (for growth), or dual.

The properties of grow LEDs

- Generate little heat, fan with less power/current consumption can be used

- High efficiency (depending on the model)

- Long service life, even after 50,000 hours they still produce 70% of the original light output

- Small compact size

- Low power consumption, energy cost savings

- The LED lamp can be brought closer to the flowers, which automatically provides plants with more light

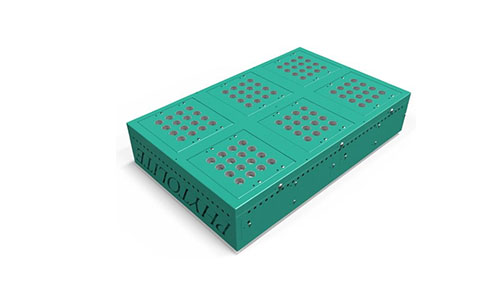

- take up little space in the grow room, are compact, no additional accessories (such as reflector or ballast) necessary

Basically, with all lamps, the more watts the higher the luminous intensity and the higher the luminous intensity, the better the results will be in terms of quality and yield. Sunlight is the best light for plants, it has the largest colour spectrum, which cannot be easily reproduced with artificial light. Artificial light can only begin to replace the sun. Sunlight has an illumination level of 100,000 lumens/m² on sunny days. LEDs come very close to the broad colour spectrum of the sun.

1W LEDs are not as bright and sufficient as the new 3W LEDs. At the same time, LEDs of the same wattage can have different brightness. LEDs require a series of resistors or a transformer to provide the precise voltages and consistent current flow needed for effective lighting and efficiency.

LEDs need the right ambient temperature to function as intended. If the temperature in the cultivation room becomes too high, not only the plants suffer, but also the LEDs. They become too warm and then produce less light.

LEDs are operated with milliamperes (mA). The science and technology behind this is complex and would go beyond the scope of this article. The actual light output is confusing and not easy to recognise for the private grower. For example, a 3W LED operated at 350mA produces 1W of light.

Grow LEDs that are too small can heat up too quickly and then lose their efficiency. Light energy is transformed into heat at a certain operating temperature. The right temperature enables the individual LEDs, regardless of type and colour, to produce the intended light spectrum. Our Orion Grow LEDs, for example, have 2 powerful fans inside and an air-cooled housing so that they cannot get too warm.

LEDs must be protected from high humidity and the wetness outside, i.e. they can be used in the greenhouse and of course indoors, but not outdoors.

The production of high-performance LEDs for plant cultivation requires a high degree of control of the individual manufacturing processes. Therefore, even more important than rapid developments in this field is high-quality and controlled manufacturing. Only through strict control and improved manufacturing processes can LEDs be produced that generate the same luminous intensity and wavelength, otherwise the differences from chip to chip can sometimes be serious. In the case of high-quality LEDs (e.g. Orion LED panel), the chips are tested individually and sorted out if they do not meet the specifications. This is a necessary prerequisite for the highest possible efficiency of the LEDs, because no two chips are alike, each one is individual, so to speak.

LEDs and costs

Due to their complex manufacturing process and the large reject rate during production, LEDs generally have a higher purchase price than many other light sources such as sodium vapour lamps. High-quality LED chips with a high luminous efficacy cost considerably more than inferior chips. On the other hand, LEDs are significantly more durable than NDLs.

LEDs and heat

Every electrical device generates heat, including LEDs. All energy absorbed by an LED is converted into either heat or warmth. An LED is most efficient when it produces little heat and at the same time produces a large amount of light. The cooler LEDs stay, the more efficiently they can work and the longer their life span.

LEDs and their rated power (watts)

There is a lot of confusion about the rated power (wattage) of LEDs. The power of an LED is given in watts. However, this wattage does not indicate the actual power consumption of the LED in watts. LEDs (LED chips) have e.g. 1W, 2W, 3W..... The indication of their wattage is a kind of classification and has no real connection with their actual power consumption. 1W LEDs normally work with 350 mA and 3W LEDs with 700 mA. A higher wattage does not automatically mean more efficiency.

LEDs and their luminous intensity

When individual LEDs are grouped together, they can produce enough light to grow medicinal cannabis. An LED panel should be 30cm or less from the plant tips to be an effective light source for cannabis plants.

Modern LEDs produce 40 to 70 lumens per watt, depending on the manufacturer. More can be expected here in the future. But the lumens per watt are only part of the story. The luminous intensity of LEDs is specified in 2 different ways depending on the wavelength. LEDs with a wavelength between 640 nm and 460 nm are specified in lumens. LEDs with a wavelength longer than 640 nm and shorter than 460 nm are specified in their radiant flux in mW (milliwatts).

Lumens are not a good unit of measurement for the luminous intensity of LEDs. The unit of measurement lumen was made for visible light as it appears to the human eye. Not all light colours are measured equally. Lumen was developed to evaluate white light sources less for the comparison of LEDs. The spectrum of each individual LED is decisive for the light output. LEDs are monochromatic, which means that unlike CFLs, for example, they produce only one light colour from a wide range of wavelengths.

To the human eye, white light that is cool-white, i.e. has a higher blue component, appears brighter than light that is warm-white, i.e. has more red components. This is why fluorescent tubes with cool-white have more lumens than those with warm-white (at the same wattage), although they do not actually have more photons (energy particles).

Most LED grow lamps contain LEDs with the following wavelengths:

- dark red: 660 nm

- red: 630 nm

- blue: 470 nm

- royal blue: 450 nm

or also:

- orange: 740 nm

- yellow: 590 nm

- green: 530 nm

- UV (technically near UV): 390 nm

LED lamps have the great advantage that the different wavelengths can be combined in such a way that they can be used most efficiently by the plants. LED technology allows developers to achieve very high PAR values. In addition, the light from LEDs can be focused and intensified by special lenses (see Orion LED).

LED lamps/panels should be hung approx. 30 cm above the plant tips to achieve good results, no more. If the LED is hung higher, this increases the illuminated area, but at the same time the light intensity is reduced. However, too short a distance to the plants can also have a stressful effect on them and should also be avoided.

Grow LEDs do not like temperatures that are too high and can then no longer function as intended. It is therefore better to keep the temperature in the grow room in the lower ideal range.

Plasma lamps - Light Emitting Plasma (LEP)

Light emitting plasma lamps are the most common and used plasma lamps for cannabis cultivation. They are one of the newer developments in indoor lighting. A very bright light is produced with the help of high frequency. The lamps are small like a chip, less than 2.5 cm². After a longer development, plasma lamps are now produced that produce the right spectrum for cannabis and plant cultivation.

The manufacturer Gavita is a leader in the development and introduction of plasma lamps. Plasma lamps do not have a ballast, instead they have an RF generator and semiconductors that perform the same function. They have more than 90% energy efficiency and solid-state drivers prevent failures. In addition, plasma lamps produce no noise and have an extremely long life of 30,000 hours (4.5 years at 18 hours of illumination per day) and more.

LEPs produce between 115 and 150 lumens per watt. The targeted light ensures that no light is lost and all its strength can be concentrated on the plants. The energy saving is up to 45% compared to NDLs. Generate laser lamps. Plasma lamps should not be additionally cooled from the outside. They need a certain temperature to reach their full brilliance.

Properties of plasma lamps (LEP)

- Very high light quality (full spectrum)

- Long service life

- Suitable for all development phases of the plant (depending on the spectrum)

- Stable performance over the entire service life

- Available as complete lamp systems

- High energy efficiency

- Available with different light spectra for the growing phase and the flowering phase as well as with dual spectrum

- produces more light spectra with wavelengths in the range of photosynthesis, no waste of energy for light that is not useful for the plants.

- light spectrum similar to that of the sun, which contains UVA and UVB rays. Ultraviolet light causes more colour, more flavour and aromas in plants. Powdery mildew is prevented by ultraviolet rays.

- little heat generation: cost saving on ventilation, the plasma lamp can be brought closer to the plants

- A 300W LEP is equivalent to a 600W NDL.

Plants grown under plasma light often need more calcium and magnesium because photosynthesis is more efficient. The growing cycle needs to be faster. Tests have shown that a combination of NDLs and LEPs provides the highest yield and quality possible. Plasma lamps have a high purchase price, but this is amortised due to the energy savings and the long service life.

What luminous intensity (lumen)?

In the growing phase of cannabis, there should be at least a light intensity (number of lumens) of 15,000 lumens per m². In the flowering phase, there should be a minimum of 30,000 l umens per m². Anything less than this will significantly reduce the growth of the cannabis plant and result in scrawny and weak growth and fewer leaves. Even better are 25,000 lumens during the growing phase and 50,000 lumens during the flowering phase . Even more lumens are even better.

Luminous intensity of NDLs:

- 250W -> approx. 31,000 lumens, effective area 0.5 m²

- 400W -> approx. 55,000 lumens, effective area 0.7 m²

- 600W -> approx. 98,000 lumens, effective area 1.2 m²

How many hours of light do cannabis plants need?

- During the growing phase , 18 hours of light within 24 hours. (i.e. 18 hours of light and 6 hours of total darkness).

- In the flowering period, 12 hours of light within 24 hours. (i.e. 12 hours of light and 12 hours of total darkness).

It is important to stick to these exposure times throughout, because cannabis plants are strongly dependent on this light cycle for their development and flowering. The exception are automatic varieties, which flower regardless of the exposure time.

The right distance between lamp and plant

- 250W NDL: at least 20cm

- 400W NDL: at least 40cm

- 600W NDL: at least 50cm

- 1000W NDL: at least 90cm

- Fluorescent tubes: about 5-10cm. So get close, the bulb won't get hot enough to burn the leaves.

If you provide further cooling, such as additional ventilation and/or use of a cooltube, the distance can be reduced even more.

How long should clones be kept in the growth phase?

Normally, clones should be allowed to grow for 1 week with 18 hours of light. If you only want the plants to become smaller, you can shorten this time, but you should let the cuttings grow for at least 3 days, because they first have to settle in and become stronger. A longer growth time for cuttings is of course always possible (and often good), then the plants will become bigger and bushier. This is a question of space or also a question of the cultivation method (-> SOG or Scrog).

<< Beleuchtung bei 1000Seeds kaufen>>