The strongest cannabis oil in the world: cannabis distillates

All about cannabis and THC distillates: use, benefits, production.

What are THC distillates/cannabis distillates?

In the meantime, there are a large number of different cannabis extracts, e.g. Wax, Shatter, BHO, Rosin, etc.. A relatively new form of extracts are the THC distillates. THC and cannabis distillates are currently one of the most expensive consumer products around and will be the future in cannabis concentrates. With unbeatable purity, clarity and potency, THC distillates offer endless uses. The short path distillation process used for this purpose is nothing new and has been used for many decades in various fields.

THC distillates and cannabis distillates differ from BHO and other extracts

One example is distilled water, which is evaporated and rapidly cooled so that it returns to its liquid form. In this way, water is purified. THC distillates are made from cannabis extracts, which undergo what is known as short-path distillation. All kinds of extracts can be used for this purpose: CO2 extract, BHO or ethanol extract. The highest quality THC distillates are made in laboratories and by professionals/chemists. During the process, all impurities and unwanted plant substances are eliminated.

Cannabis distillates are absolutely pure and also contain no chlorophyll. Pesticides, impurities and fungi are removed within the process. Their cannabinoid content can reach 99%. The whole process is much more complex than that of BHO production. Laboratories producing cannabis distillates today use fully automated systems that perform decarboxylation, winterization and fractionation/short path distillation step by step.

Within the process, partially explosive substances such as ethanol are heated and cooled down again. Accordingly, this requires the necessary equipment and, above all, a comprehensive knowledge of the processes. If this is not available, it is better to leave it alone.

In short, THC distillates currently represent the purest, clearest, and most potent concentrates available.

How does THC distillate differ from BHO?

THC distillates are more potent and pure than BHO. In addition, the production of these two extracts differs significantly. BHO is produced by using butane gas to separate the THC from the plant parts/flowers. The final product can have different consistency and color. The purest form of BHO is shatter, which is very hard and can break like glass.

BHO can reach a THC content of up to 70%. Through winterization, even up to 80% can be achieved. However, one can push the process of purification and concentration even further by distilling winterized BHO. This means: one can make THC distillates from BHO, but a THC distillate does not become BHO.

THC distillates are relatively new, emerging around mid-2015, while BHO and CO2 extracts emerged about 10 years ago. THC distillates are sold in the U.S. in small needles or capsules and are usually dabbed. THC distillates can also be dripped under the tongue or used as additives in various dishes.

Does the THC distillate have to be decarboxylated beforehand?

In the course of production, the cannabis is decarboxylated. Distillates that are sold and produced in the lab are of course already decarboxylated. You can also mix THC distillate with e-liquids and make your own highly potent liquid for vaporizing this way. Especially suitable for this are the E-liquid sets from Fram to Vape..

What is the advantage with cannabis distillates?

Although smoking marijuana is less dangerous than tobacco, some undesirable byproducts are present in the flowers (e.g., plant waxes, chlorophyll, etc.). Especially for users and patients who require very high doses of THC, weed in higher amounts can be stressful to the lungs. THC distillates have no odor and contain no byproducts. How could they, they are 99% pure THC. The terpenes are fractionated i.e. separated within the short path distillation.

THC distillates are 4-8x stronger than weed and only recommended for experienced users. Since we can now assume that the high of cannabis is to a significant extent co-controlled and influenced by the terpenes and the other cannabinoids, it makes sense to mix these distillates specifically with the desired terpenes (or cannabinoids) or the terpenes that have already arisen from the distillation process afterwards. This, of course, offers an unlimited variety of control options in terms of high and medicinal effect.

Myrcene, one of the most abundant terpenes in cannabis influences whether a cannabis strain is sedative or stimulating. Terpinolene, α-pinene, linalool, limonene and other terpenes have positive effects on anxiety, cancer, inflammation and epilepsy. So there are also many benefits to keeping track of and using all the components of the cannabis plant.

THC distillates in detail

Let's go into a little detail to see exactly how it's done. It's going to get a little complicated now. First, we need to dig out a bit and take a closer look at short path distillation. Short Path Distillation is a distillation method that requires distillates to pass through a short path (just a few inches). This is usually done with reduced pressure.

This technique is mostly used for components that are sensitive to higher temperatures or to purify smaller quantities of components. Short Path Distillation achieves a reduction in boiling temperature by lowering the operating pressure.

This is a continuous process in which the heating temperature under reduced pressure can be significantly lower than the boiling point of the liquid at normal pressure. The distillate only has to travel a short distance before condensation, which in turn ensures that few compounds are lost.

Ball-tube distillation is a type of short-path distillation apparatus that often contains several chambers for collecting distillate fractions. This method is used for compounds that are unstable at high temperatures because it allows the use of a low boiling temperature. It is further a method for separating mixtures based on differences in their volatility.

Short path and molecular distillation were developed in the 1930s and 1940s and were mainly used in the USA and Great Britain. In short-path distillation, the vapors produced are no longer in contact with the liquid.

If THC distillates and other cannabis distillates are to be produced, some accessories are necessary:

- a rotary evaporator

- a short path distillation system

- A cold trap

- a vacuum pump

- one cooling pump

- Activated carbon powder for filtering

- Büchner filter

- different beakers

- Micronet filter

- Laboratory filter

- Magnesium silicate powder

Short Path Distillation Guide

In the following Short Path Distillation Guide the proper steps are described to perform a complete fractional distillation run from start to finish.

Step 1: the extraction

First, the oils/cannabinoids must be extracted from the plant material. This can be done with an extractor and butane gas, CO2 or with ethanol. We use ethanol in the following because it is a very safe, reliable and simple method.

- Coarsely chopped plant material, more specifically, the best buds you can get, are placed in cold ethanol and stirred for 10 minutes.

- Then filter the plant material out of the liquid using a coffee filter or a very fine mesh micronet (220µg).

- Now filter the liquid again with an even finer filter net with 73µg. This will remove even the smallest particles from the liquid.

Step 2: Reduction

Our ethanol-cannabis liquid is now to be reduced, i.e. the ethanol is to be removed again. The fastest way to do this is in the laboratory with a rotary evaporator. The solution is to be reduced to about half its volume.

- 3L cannabis solution is filled into a 5L rotary evaporator

- Ice-cold water is fed to the condenser of the rotary evaporator by means of a cooler pump.

- After filling the boiling flask with 3L of cannabis solution, we lower it into the water bath of the rotary steamer, which is heated to 35°C.

- Now we put the system under vacuum to create an inert atmosphere. The vacuum separates the ethanol from our crude oil. The ethanol solution is reduced to half.

Step 3: Winterization

We take this raw mixture and mix it with ethanol in a 1:1 ratio. Then the liquid is placed inthe freezer for 24 hours. After 24 hours, we filter the solution with a fine mesh micronet filter or coffee filters. This process is repeated until the solution is no longer milky or cloudy when you take it out of the freezer.

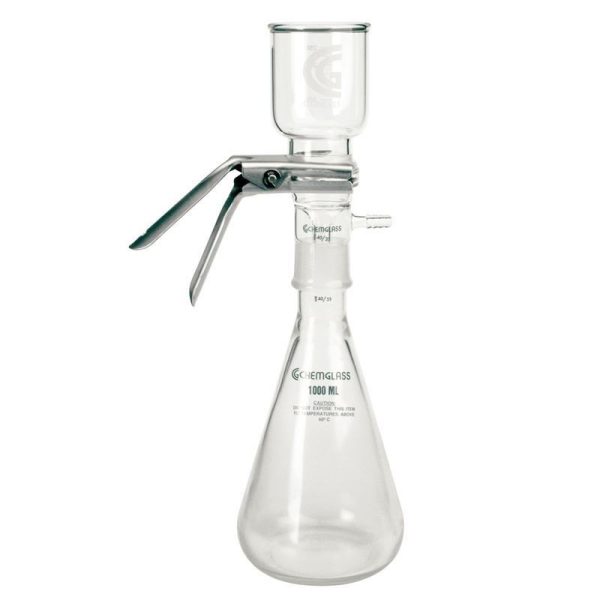

Step 4: Filter

A Büchner filter (Nutsche), a vacuum pump and a vacuum filter, are used in the next step. At this point, our solution is dark green, sometimes almost black due to the high concentration of molecules. Filtering is one of the most important steps to produce a high quality and pure cannabis concentrate.

A vacuum filter helps to get the smallest particles out of the cannabis extract

- Use a 3-5L beaker into which you put about 2L of the solution.

- Add 10 teaspoons of activated charcoal powder and stir well. It is best to wear a respiratory mask because of the fine carbon dust.

- Now place this mixture on the hot plate (at 37° C) and stir with the magnetic stirrer for 10 minutes.

- Prepare the vacuum filter and equip it with a filter paper with a high flow rate. Place the cold trap between the vacuum and filtration device lines to collect the excess steam.

- Cover the filter paper with 15ml of magnesium silicate powder.

- Switch on the vacuum pump.

- Slowly pour the liquid into the upper funnel until it is full.

- Continue the process until the beaker is empty.

- If your solution is not yet clear and golden, repeat this process.

The cold trap catches excess condensate

Step 4: Reduce

We proceed in the same way as we just did and use a rotary evaporator to best reduce the filtered liquid. The material should then have a viscous consistency so that it can then be distilled in the Short Path Distillation.

- The solution is filled back into the 5L rotary evaporator.

- Ice-cold water is fed to the condenser of the rotary evaporator by means of a cooler pump.

- After the boiling flask is filled with about 3L of cannabis solution, we lower it into the water bath, which is heated to 35°C.

- Again, the system is placed under vacuum to create an inert atmosphere. The vacuum separates the ethanol from the cannabis oil.

- We repeat these steps until all ethanol is separated from the cannabis oil and we have only the cannabis oil.

Step 5: first pass of short path distillation

So, now we have a clean crude oil to distill in our short path still. Now comes the distillation process itself. When a crude oil is distilled for the first time, it is called a first pass. In the first pass, the crude oil is put through its first distillation.

- Fill a 5L piston with 2.5L of crude oil.

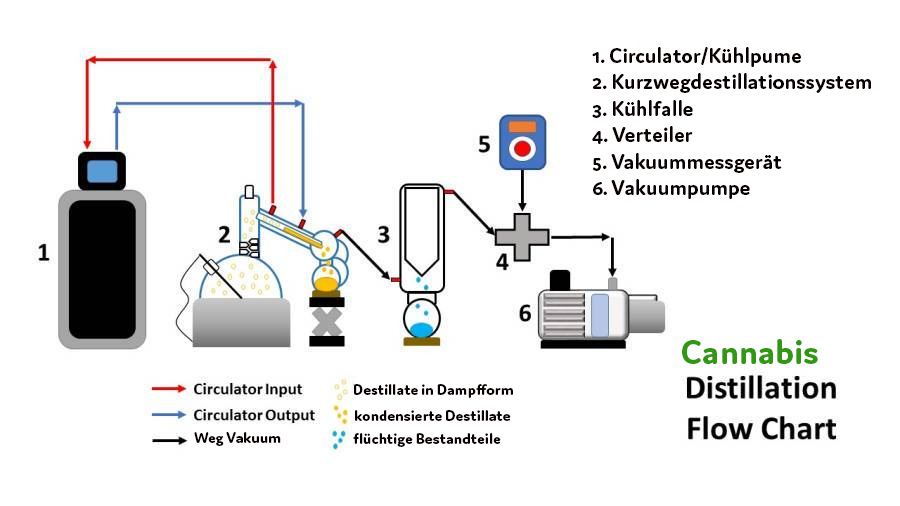

- Now set up the Short Path Distillation as shown in the diagram below:

- When the system is set up as intended, the vacuum pump is started and the system is checked for vacuum leaks.

- After ensuring that there are no vacuum leaks, we switch the hot plate to 38° C and the magnetic stir bar is set to 600rpm.

- We let the crude oil decarboxylate for 45-60 minutes.

- When this is done, the actual distillation begins.

- When the cannabis oil is heated to 38°C, the temperature can be slowly increased by 15°C every 30 minutes. This ensures that residues of ethanol or water are removed.

- When 60° C is reached, fractionation of individual components slowly begins. We can see oil vapors condensing from the flask in the distillation head and collecting droplet by droplet. Meanwhile, the flask continues to be heated up to 75° C.

- When the temperature goes towards 82° C, the evaporation of some terpenes already starts, which collect in the first collecting flask. The color of the collecting flasks varies from clear yellowish to bluish.

- After the terpenes have been collected, we slowly increase the temperature to 100-107° C. At this temperature we see the true nature and appearance of THC-D9 as it collects in the condenser. However, we need to run 15ml of the main fraction through the condenser to really get the cleanest fraction.

- In the following, the temperature is further increased to 110° C. The THC-D9 is "in free flight".

- We now switch to our main flask by turning our manifold slightly towards the center flask. Now it's on to the real thing, so pay close attention to the change in color and temperature. If the color changes, this is an indicator that you are moving from THC-D9 fractionation to CBD fractionation.

- As soon as the temperature change and the change of color occurs, we switch to the third collecting flask on the manifold.

- We turn off the heat and the last fractionation comes to its end.

- The vacuum pump continues to run until the temperature in the large flask (on the hot plate) has dropped to 140° C.

- The receiving flask is removed from the system for our next step.

Step 6: Dry cleaning

After our first pass in the distillation process is complete, we are ready for chemical purification of the oil. The chromatography column or separation funnel can be prepared.

- After the preparations are made, we dilute our first pass material with hexane in a ratio of: distillate of about 4: 1.

- Then we prepare a salt solution of distilled water and sodium chloride.

- The hexane distillate mixture is poured into a 3L flask and stirred without heat using the magnetic stirrer.

- The salt solution is mixed with the distillate(+hexane) in a ratio of 1:1 and stirred in a magnetic stirrer for one hour.

- This mixture is now placed in the chromatography column. So that the individual components separate. The salt solution settles to the bottom together with our water-soluble and unwanted particles, while the distillate remains in the hexane layer.

- With the drain on the chromatography column, the water layer is slowly removed.

- After removing the water layer, we pour the distillate-hexane mixture into our 5L flask of the rotary evaporator. Now the separation of the hexane solvent from our now very clean second pass material is to be performed.

Step 7: Reduction

Now comes the reduction of the solution. The rotary evaporator is used to reduce the amount of hexane in the solution. Alternatively, a long path distillation setup can be used for this purpose.

- We take 3L of solution and pour it into our 5L rotary evaporator.

- Cold water (0° C) is fed to the condenser of the rotary evaporator by means of the cooling pump.

- After filling the boiling flask with the 3L, we lower the flask into the water bath, which was heated to 30°C.

- We apply vacuum to the system and create an inert atmosphere. The vacuum causes the separation of the hexane solution from the distilled oil, which we want to have.

- Once the solution has reduced and all hexane has been removed, only the oil remains.

Step 8: Last pass

This is already our last step to perform in the short path distillation. The procedure is similar to the first pass, but the decarboxylation is omitted.

- We fill the 5L piston with 2.5L oil.

- Next, we prepare the cleaned short path distillation system as we did in the last run.

- We again apply vacuum to the system and check for vacuum leaks.

- Once the oil reaches a temperature of 38° C, we can increase the temperature by 15° C every 30 minutes.

- From 60° C already begins the evaporation of the different bandwidths (ingredients). We can see how the oil evaporates in the flask and condenses in the distillation head. Drop by drop we approach 65° C in the 5L flask.

- At 85° C we can see how more terpenes evaporate and end up in the 1st collecting flask.

- After the first receiving flask is filled, we slowly increase the temperature to 100-107° C, the THC-D9 emerges and becomes visible in the condenser. About 15ml of the main fractionation must pass to ensure the purest distillates.

- At 125° C, the THC starts to become volatile and we move to the next receiving flask.

- During the collection of the THC-D9, close attention must be paid to color and temperature changes. This is an indicator that THC fractionation has ended and is moving into CBD fractionation.

- As soon as the color change occurs, we switch to the third collecting flask.

- The temperature is lowered as soon as the last fractionation has come to an end.

- The vacuum pump continues to run until the temperature in the 5L flask has dropped to 62° C.

- Take the collection flasks out of the system: you have it in your hands: pure THC-D9 and pure CBD. Cleanly separated, infinitely expensive and one of the most sought-after products at the moment.

Note: Due to the vacuum, the respective boiling points are lowered and are lower than usual!

The extent to which the boiling points of the respective cannabinoids and terpenes are lowered depends on the strength of the vacuum that exists in the system.

Using THC-D9 as an example:

- at 0% vacuum Boiling point at 157° C

- at 21% vacuum Boiling point at 152° C

- at 50% vacuum Boiling point at 142° C

- at 74% vacuum Boiling point at 128° C

- 96% vacuum Boiling point at 93° C

The way of cannabis/THC distillation is a long and complex one as you can see from the description. If you have come this far in the text, you know that a really large amount of starting material must be used, because otherwise the results will remain in the microscopic range. The initial cost of the Short Path Distillation and the necessary accessories is relatively high, the time required is enormous and it is usually performed by professionals within special laboratories and usually fully automated.

So you have to be quite a freak, deep cannabis enthusiast with a penchant for science and experimentation, and preferably also be commercially active in this field so that it is feasible. But who knows, maybe there is someone among you who bites through and one day holds his own pure THC distillate in his hands.

You can find more grow tips and cannabis topics in our Grow Lexicon.