LEDs for growing - lots of light, low costs and what's new

It is no longer possible to imagine life without LEDs. They are on various appliances, on the Christmas tree or advertising signs. Since LEDs were invented in 1962, they have come a long way. While the first ones had only a very low luminous flux, LED technology progressed rapidly and produced much brighter and more efficient LEDs. LEDs are now available in the entire visible light spectrum and from ultraviolet to infrared.

Many cannabis growers who cultivate medicinal cannabis use LEDs. They are used in the germination and grow phase, but also during the flowering phase. There are now countless different types of LEDs on the market. In some cases, it is not easy to immediately recognise from the data which LED may be different from another.

LEDs use solid-state semiconductor energy to generate light. The technology is similar to that found in computer circuits. They do not use gas like, for example, NDLs or energy-saving lamps. At the same time, LEDs generate less heat. The luminous efficacy of LEDs increases with high-quality processing and the use of improved materials.

The advantages of modern grow LEDs

- Generate little heat, fan with less power/current consumption can be used

- High efficiency (depending on the model)

- Long service life, even after 50,000 hours they still produce 70% of the original light output

- small size

- Low power consumption

- The LED lamp can be brought closer to the flowers, which naturally provides plants with more light

- take up little space in the grow room, are compact, no additional accessories (such as reflector or ballast) necessary

- Plug & Play: LEDs are immediately ready for use. They only need to be placed in the grow box and you're ready to go.

High-quality LED panels with sufficient power and the right colour spectrum of light can produce resinous and sticky buds alone without any further lighting

1W LEDs are not as bright and sufficient as 3W LEDs. At the same time, LEDs of the same wattage can have different brightness. LEDs require a series of resistors or a transformer to provide the precise voltages and consistent current flow needed for effective illumination and efficiency.

LEDs need the right ambient temperature to function as intended. If the temperature in the cultivation room becomes too high, not only the plants suffer, but also the LEDs. They become too warm and then produce less light.

LEDs are operated with milliamperes (mA). The science and technology behind this is complex and would go beyond the scope of this article. The actual light output is confusing and not easy to recognise for the private grower. For example, a single 3W LED operated at 350mA produces 1W of light.

Grow LEDs that are too small can heat up too quickly and then lose their efficiency. Light energy is transformed into heat at a certain operating temperature. The right temperature enables the individual LEDs, regardless of type and colour, to produce the intended light spectrum. Our Orion Grow LEDs, for example, have 2 powerful fans inside and an air-cooled housing so that they cannot get too warm.

LEDs must be protected from high humidity and the wetness outside, i.e. they can be used in the greenhouse and of course indoors, but not outdoors.

The production of high-performance LEDs for plant cultivation requires a high degree of control of the individual manufacturing processes. Therefore, even more important than rapid developments in this field is high-quality and controlled manufacturing. Only through strict control and improved manufacturing processes can LEDs be produced that generate the same luminous intensity and wavelength, otherwise the differences from chip to chip can sometimes be serious. In the case of high-quality LEDs (e.g. Orion LED panel), the chips are tested individually and sorted out if they do not meet the specifications. This is a necessary prerequisite for the highest possible efficiency of the LEDs, because no two chips are alike, each one is individual, so to speak.

LEDs and costs

Due to their complex manufacturing process and the large reject rate during production, LEDs generally have a higher purchase price than many other light sources such as sodium vapour lamps. High-quality LED chips with a high luminous efficacy cost considerably more than inferior chips. On the other hand, LEDs are significantly more durable than NDLs.

LEDs and heat

Every electrical device generates heat, including LEDs. All energy absorbed by an LED is converted into either heat or warmth. An LED is most efficient when it produces little heat and at the same time produces a large amount of light. The cooler LEDs stay, the more efficiently they can work and the longer their life span.

LEDs and their rated power (watts)

There is a lot of confusion about the rated power (wattage) of LEDs. The power of an LED is given in watts. However, this wattage does not indicate the actual power consumption of the LED in watts. LEDs (LED chips) have e.g. 1W, 2W, 3W..... The indication of their wattage is a kind of classification and has no real connection with their actual power consumption. 1W LEDs normally work with 350 mA and 3W LEDs with 700 mA. A higher wattage does not automatically mean more efficiency.

LEDs and their luminous intensity

When individual LEDs are grouped together, they can produce enough light to grow medicinal cannabis. An LED panel should be 30cm or less from the plant tips to be an effective light source for cannabis plants.

Modern LEDs produce 40 to 70 lumens per watt, depending on the manufacturer. More can be expected here in the future. But the lumens per watt are only part of the story. The luminous intensity of LEDs is specified in 2 different ways depending on the wavelength. LEDs with a wavelength between 640 nm and 460 nm are specified in lumens. LEDs with a wavelength longer than 640 nm and shorter than 460 nm are specified in their radiant flux in mW (milliwatts).

Lumens are not a good unit of measurement for the luminous intensity of LEDs. The unit of measurement lumen was made for visible light as it appears to the human eye. Not all light colours are measured equally. Lumen was developed to evaluate white light sources less for the comparison of LEDs. The spectrum of each individual LED is decisive for the light output. LEDs are monochromatic, which means that unlike CFLs, for example, they produce only one light colour from a wide range of wavelengths.

To the human eye, white light that is cool-white, i.e. has a higher blue component, appears brighter than light that is warm-white, i.e. has more red components. This is why fluorescent tubes with cool-white have more lumens than those with warm-white (at the same wattage), although they do not actually have more photons (energy particles).

Most LED grow lamps contain LEDs with the following wavelengths:

- dark red: 660 nm

- red: 630 nm

- blue: 470 nm

- royal blue: 450 nm

or also:

- orange: 740 nm

- yellow: 590 nm

- green: 530 nm

- UV (technically near UV): 390 nm

LED lamps/panels have the great advantage of being able to combine the different wavelengths so that they can be used most efficiently by the plants. LED technology thus allows designers to achieve very high PAR values. In addition, the light from LEDs can be focused and intensified through special lenses. To achieve good results, you should make sure to use led lamps that are suitable for cannabis cultivation and that produce sufficient light intensity and the right light spectrum. This is the only way to grow large and potent buds. LEDs like the Orion or the Quantum X meet industrial standards and are suitable for producing correspondingly thick harvests. They can be used from germination to harvest.

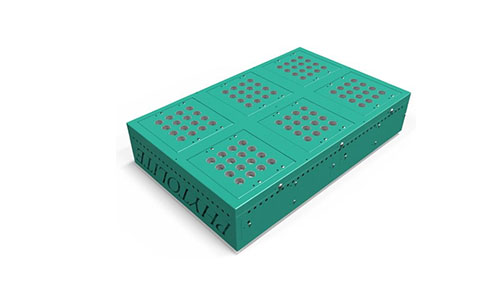

Quantum X from Phytolite

Maximise your LED grow

Water consumption

When switching from sodium vapour lamps to LED lamps, cannabis gardeners easily make the mistake of overwatering their plants. LED lamps generate much less heat, the soil dries out correspondingly slower and the general water consumption decreases.

correct distance to the plant tips

LED lamps/panels should be hung approx. 30 cm above the plant tips to achieve good results, no more. If the LED is hung higher, this increases the illuminated area, but at the same time the light intensity is reduced. However, too short a distance to the plants can also have a stressful effect on them and should also be avoided.

Temperature in the grow room

For the sake of the plants alone, the temperature in the grow room should be controlled and not be too hot (use a sufficient fan + good fresh air supply). Grow LEDs also do not like too high temperatures and can then no longer function as intended. It is therefore better to keep the temperature in the grow room in the lower ideal range.